A More Efficient Airline Meal Tray

A recent innovation in the design of the airline meal tray has resulted in massive savings. Maybe the next innovation should focus on the actual food

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/food_tray_header.jpg)

In the airline industry, the old notion of “a penny saved is a penny earned” translates to something more like “an inch saved is a million earned.” Eliminating storage space, supply carts, or even an extraneous piece of paper from an aircraft can direct money back into the business in the form of extra seats sold, or simply by reducing weight and in turn economizing on fuel (oh, and shrinking the carbon footprint).

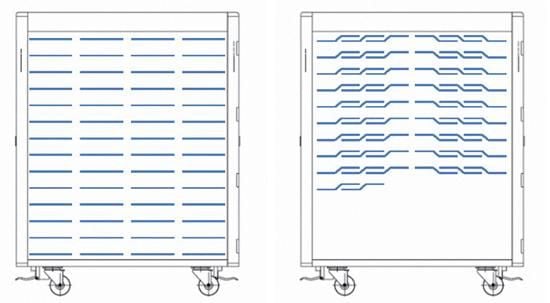

A recent innovation in the design of the airline meal tray has contributed to a massive savings for companies choosing to make the switch. Gate Gourmet, whose ubiquitous catering trolleys pull up to nearly every plane in every airport to replenish the galley between flights, employs an in-house design team called potmstudios that works almost exclusively on developing better in-flight accoutrements. In 2010, they deployed a reconsidered, stackable meal tray that takes up at least 35 percent less space in the cart, and enables a whole new chain of food preparation and delivery on the ground.

Since most U.S. airlines have eliminated the hot meal option from in-flight service altogether, a brief reminder of what that relic (which still exists in many parts of the world) looks like: About one-half to two-thirds of the tray is occupied by cold items—a roll, a salad, a gelatinous dessert—while the remainder contains a hot entrée, such as chicken piccata or beef stroganoff (hungry?).

Up until the invention of this new nesting meal tray, the hot entree container was stored separately from the rest of the meal so that it could be heated before serving, leaving unused space on each and every one—a gross inefficiency when measured at scale. According to an article from the Airline Passenger Experience Association (APEX) published this year, Filip Fransen, a designer at potmstudios in Singapore, identified the critical problem: too much unexploited air.

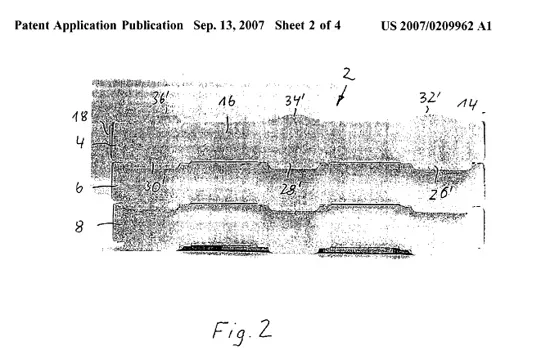

A Google Patent search for Mr. Fransen’s name reveals two patent applications from 2006 and 2007 for inventions designed to improve the serving of food on board a plane, one of which is called a “stackable tray,” though it doesn’t precisely resemble the product released by Gate Gourmet.

The solution that’s now in use by airlines in New Zealand, Brazil, and elsewhere, is an interlocking tray system that enables the empty side of each tray to slide under the body of the next one until it’s time for a flight attendant to pull it out and fill it with a hot entree. They called the Lean-On-Me tray. To economize even further, the larger boxes in which the trays are stored and delivered can be turned into disposal containers after the meal service, eliminating the need for garbage trolleys.

Unfortunately, while all this innovation has helped the airlines conserve on money, material, fuel, and emissions, it probably hasn’t improved the food. The company realized it could keep pushing meal service efficiency by combining the Lean-On-Me tray with an entirely boxed meal containing primarily shelf-stable ingredients that could be packed off site and didn’t require refrigeration or heat. So if you’re looking for something fresh, the best policy is to bring your own, and hope vegetables are never considered a liquid.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/sarah-rich-240.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/sarah-rich-240.jpg)